Leverage our years of expertise at every phase of your project.

Let our team become your team

As the world’s leading provider of clinical centrifuges, Drucker Diagnostics produces private labeled products for more than 150 partners including the world’s largest reference labs, distributors, and hospital networks. But did you know that we also offer a variety of high-quality manufacturing services?

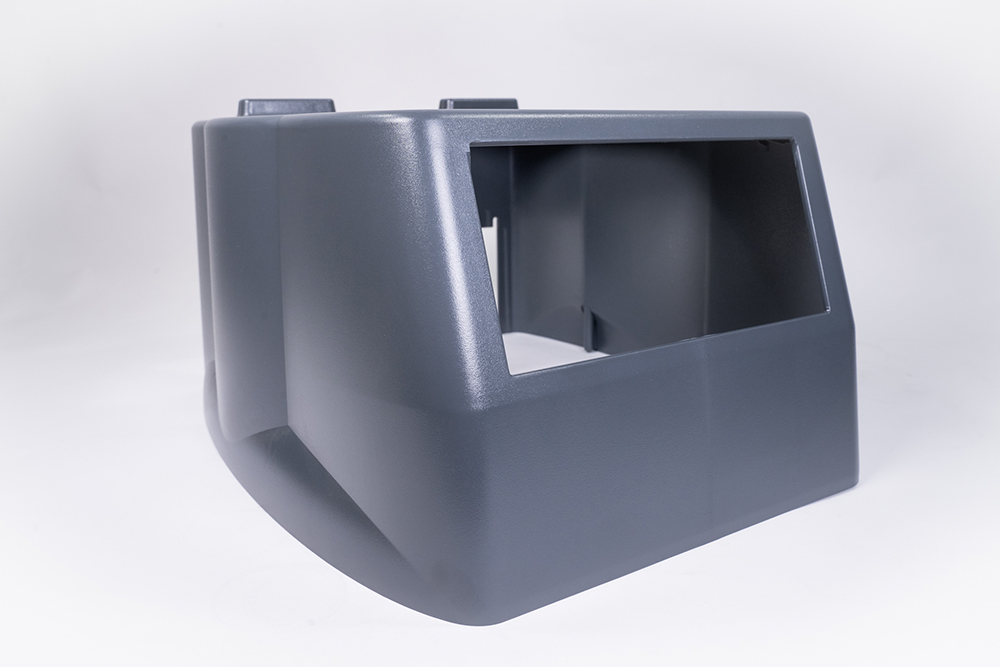

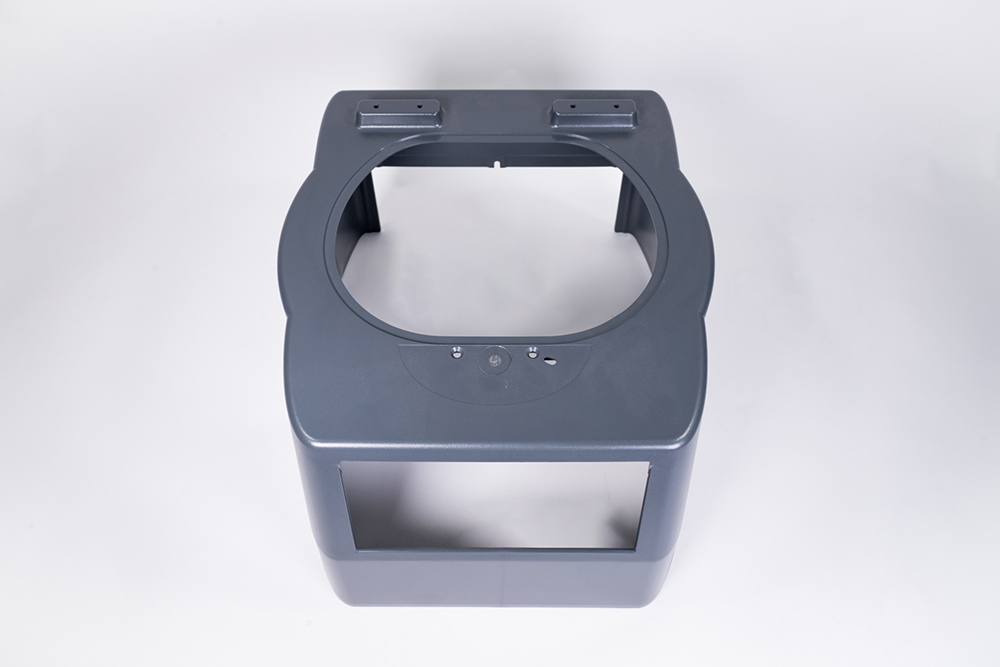

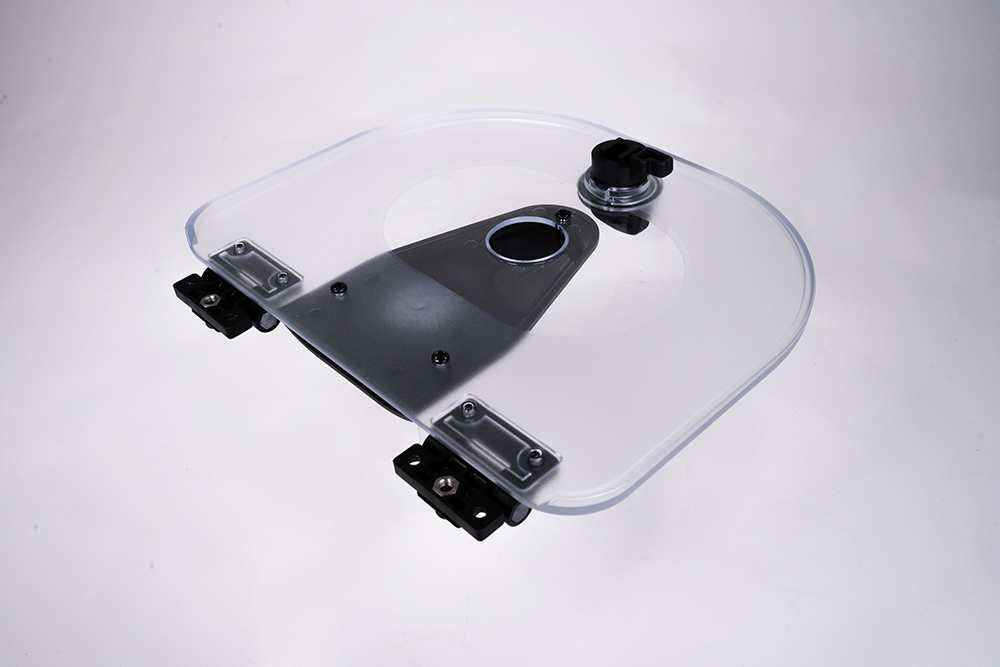

Our in-house manufacturing capabilities include injection molding, project design, prototyping, precision molding, and assembly—all supported by our industry-leading customer support. Whether you need custom parts or complete product development, we’re committed to providing reliable, cost-effective solutions that reduce operational risk and improve supply chain efficiency.

Why choose Drucker Diagnostics?

Vertically integrated

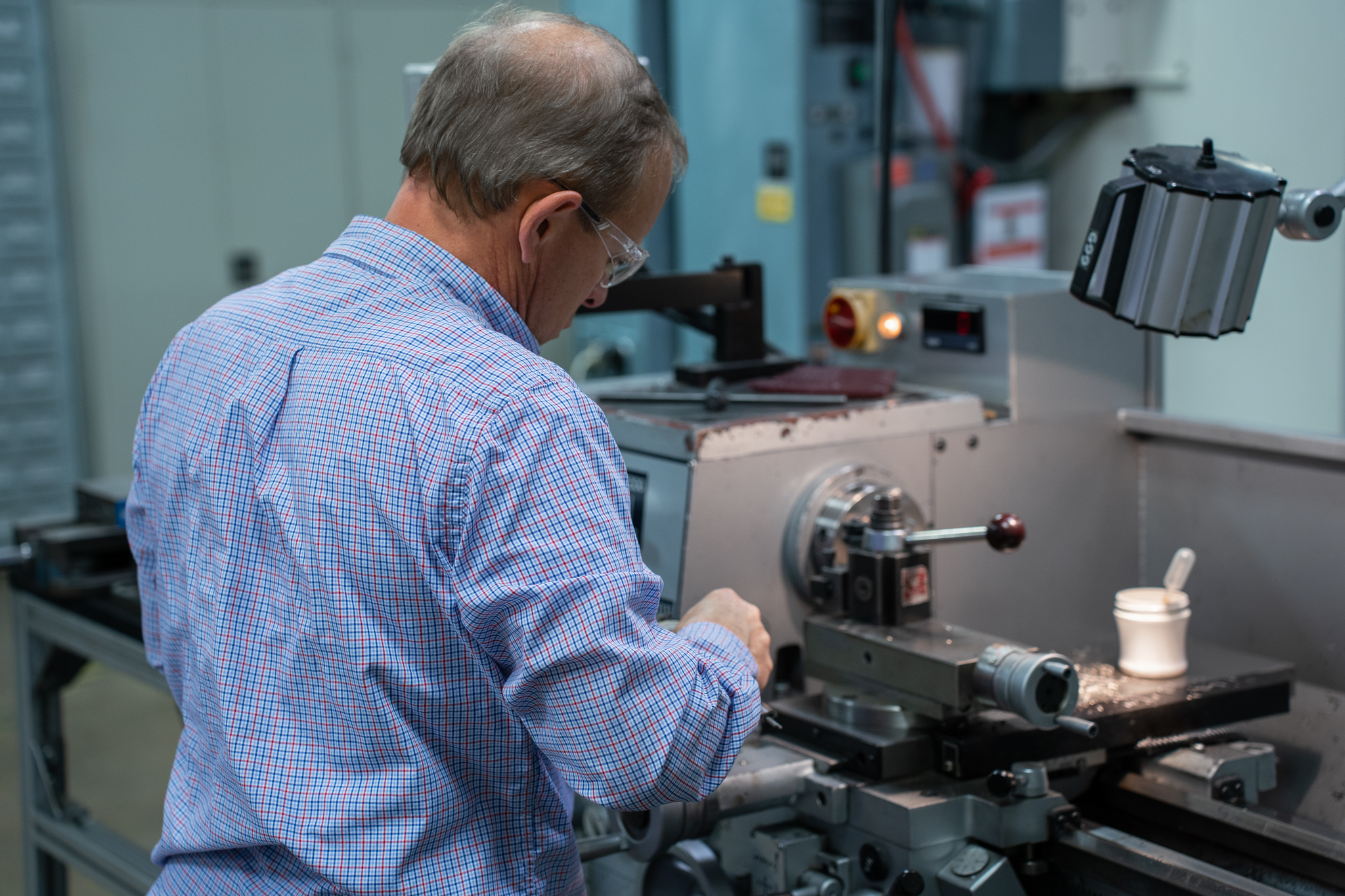

Drucker Diagnostics is a vertically integrated manufacturer with in-house design, injection molding, CNC machining, printing, metal bending and forming, instrument assembly, and more.

Quality you can trust

Our robust quality control systems are built for the high standards of medical device manufacturing.

Stateside manufacturing

For more than 80 years, the entire Drucker product line has been designed, built, and supported in Central Pennsylvania, USA.

Dedicated experts

Our trusted team includes engineers, manufacturing specialists, and designers to optimize every phase of the process.

Design and engineering support

On-demand production at any scale

Quick turnaround and fast shipping

Tight tolerance molding

ISO 13485 certified

40 – 500 ton presses

Fast and flexible manufacturing solutions

At Drucker Diagnostics, we offer end-to-end solutions for your manufacturing needs, from design and prototyping to molding and final assembly. As a US-based manufacturer, we provide fast lead times to ensure you meet even the tightest deadlines. We pride ourselves on providing custom solutions tailored to your unique design and molding requirements, delivering flexibility and precision at every step.

Leverage our years of expertise at every phase of your project. Let our team become your team.

Investing in innovation for better patient outcomes

We’re always looking for ways to improve our products and manufacturing processes. With the addition of our new 500-ton injection molding press, we’re able to expand our production capabilities and refine the design of our centrifuges to deliver faster, more reliable results for the patients and healthcare professionals who depend on them.

Streamlining centrifuge production with injection molding technology

Learn how we used injection molding technology to address high demand for the 642E, our flagship centrifuge and worldwide best-seller for offsite testing and pre-analytic sample processing. After recognizing the limitations of traditional metal parts and the need for continual innovation, we decided to explore the adoption of injection-molded plastics that are engineered specifically for medical applications.

Explore our options for value added manufacturing

- Press-side machining

- Press-side drilling

- Precision CNC finishing

- Pad printing

- Overmolding

- UV printing for complex labeling

SPECIFICATIONS

| Press | Maximum Shot Size |

| 500 Ton Press | 61.3 oz |

| 350 Ton Press | 42.4 oz |

| 100 Ton Press | 4.8 oz |

| 50 Ton Press | 2.8 oz |

| 30 Ton Press | 0.9 oz |

SPECIFICATIONS

| Press | Maximum Shot Size |

| 350 Ton Press | 42.4 oz |

| 100 Ton Press | 4.8 oz |

| 50 Ton Press | 2.8 oz |

| 30 Ton Press | 0.9 oz |